TPO ROOFING

Thermoplastic Polyolefin

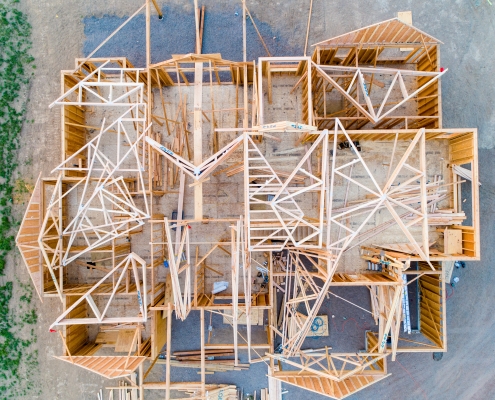

Roofs come in a variety of shapes and sizes, some of them are triangular (think A-Frames) while others are flat (think Urban Roof Tops). Each serves a different purpose, both functionally and aesthetically. (See our blog on the shapes of tiny house roofs below). For those who choose to go with a flat roof design, you must make a decision on how to protect it from exterior elements such as rain, wind, snow, etc. In this incredibly important decision, TPO rises to the top of the list! So what is TPO roofing, why does it stand out on its own and how is it installed?

Read B&B Micro Manufacturings blog on:

B&B ROOFING EXPERTS

B&B Micro Manufacturing’s roofing experts were visited by Nick of Mule-Hide Products where they learned how to properly install TPO Roofing!

WHAT IS TPO?

TPO stands for Thermoplastic Polyolefin, which is really just a fancy way of saying it’s a sheet of reinforced plastic and rubber.

TPO comes in large rolls between 4′-12′ in width depending on the design of your project. You also have the option between mechanically fastened or pre-manufactured self-adhesive rolls.

Mechanically Fastened:

No Glue … Must be Welded

More Affordable

Self-Adhesive:

Manufactured with an adhesive agent to the back of each sheet

More Expensive

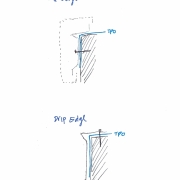

**The reason TPO can be mechanically fastened is due to the fiberglass skim that has been manufactured within the roll itself. (See Image Below)

WHY TPO?

TPO is able to provide a protective barrier that allows your tiny structure to perform efficiently and effectively without compromising on design. Flat roof designs can be tricky when dealing with tiny houses on wheels, however, TPO allows you to maintain both form and function.